Building odyssey

Rigging The Hull For Turning

Tuesday, September 21, 2010

And , after 16 months and approximately 1200 hours ( I do try to keep up with the hours on a spreadsheet) I am ready to turn the hull. The plan is to use the “ roasting spit ” method. Dix has an article about various methods of turning a hull available through his website. The basic idea is to attach a pipe at a certain level to the stem and another to the transom, which then rest on a stout pivot point. Chain hoists or a crane or forklift are then used to control the rotational motion of the hull as it flips over. The appeal of this method to me is that the hull i never suspended from any straps or chains, rather the weight is borne by the pipe and pivots.

No, that’s not a battering ram.

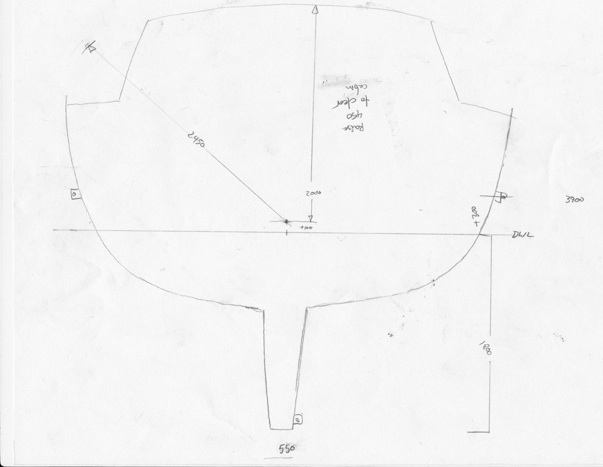

The diagram above a helped me to figure out what needed to happen: in order to clear the corners of the pilot house, the hull would need to be lifted up about 450mm, then set down -200mm from it’s original position to rest the keel on the ground. Robert at Alumar had suggested, based on some skin calculations , that the CG would be about 100-120mm above the DWL. This was also fairly close to the geometric center of the vertical axis, so seemed like a good place to start.

I designed a couple of hydraulic lifts for either end, using a 5” square steel tube sliding inside a 6” square tube, lifted by a 3 ton long-reach hand operated hydraulic jack. A section of angle iron is the pivot cradle.

The axial pipe is 4” schedule 40 steel. The section on the stern is short, about 32” , but the bow pipe has a span of 44”, so I made sure to reinforce it well. The nice thing ( one of many) about aluminum is that the welds are strong, but can easily be cut and removed later, so when attaching the pipe to the boat I wasn’t constrained in making welds. I kept imagining the boat turned sideways and how the forces would be acting on the pivot pipe and joint. I also used a cool online deflection calculator at www.calculatoredge.com/civil%20engg%20calculator/beam.htm#. I’m definitely not an engineer, but have a practical understanding of physics and mechanics, and a working knowledge of the strengths and weakness of materials, so I get by. However, this is the first 5500 pound boat hull I’ve ever turned...and I don’t want to drop it.

referenced to the same plane. The gratifying thing after doing this was that the new points matched up very closely to my originals.

Next, I welded some heavy duty padeyes , with 3 ton shackles, to either side of the hull amidship, and to one side of the keel. These shackles will hold straps attached to chain hoists attached to the rafter ( it’s a big rafter , a 12” I- beam) and to the boom on the forklift.

I greased the sliding gibs on the hydraulic jack devices and the pivot cradle, added a few angle braces to the jacks and made some calls to a few friends who I thought might like to either help in the turning, or just watch. The weather was cooling down, the rigging was ready, the hull was welded: time to turn her over...