Building Odyssey

Ballast

Saturday, July 23, 2011

Remember that 4th blog entry, Casting Lead Ingots, from May 29, 2009? Most of those ingots were cast way back in the winter of 2009. That was the first task I did on the boat, before I even had the aluminum. Now, more than 2 years later, 2500 hours, it is time to place that lead into the bottom of the keel and seal it up forever more. The basic idea is to stand on end the 3 x16” triangular ingots, each weighing around 33 lbs, packing them as closely as possible into a giant’s tetris game, then pour molten lead around them to fill in the spaces and hold them all together.

Amazingly, I had never actually tested this theory, and even more amazingly, it worked pretty well.

Packing the ingots tightly became more difficult as their number grew. I resorted to power-hammering some of them down into flatter shapes so they would fit better. I was determined to pack them tightly. I worked at the first compartment very hard. It was very hot and humid. I sweated a great deal. My back grew weary. I took many breaks, drank lots of water and kept at it. Finally, I was ready to ladle some molten lead in. What I soon realized was that by packing the ingots so tightly, the molten lead chilled too quickly and had trouble running to the bottom of the keel. I also found that heating the lead a little hotter helped it to flow. One must be very careful with lead not to vaporize it, because then it is a health hazard. Wear a respirator and gloves, and wash hands often. Launder the clothes separately from the rest of the family ( which I do anyway, ‘cause I’m known as Grubby Hubby)

Getting the lead in.

For the next compartments, I didn’t bother packing the ingots so tightly. I still tried to get them in efficiently but 1/2” gaps were fine, and the occasional 1” opening to the bottom was a good thing.

I ladled the lead for about 30 minutes at a spell, having to stop due to the heat, both in my body and which built up in the keel. Mustn’t overheat the aluminum! Occasionally I sprayed water from the hose onto the outside of the keel skin.

After I had ladled 200 or so pounds of molten lead, spread between all of the compartments, I would use my large Harris propane/oxygen rosebud torch to blast the tops of the ingots and melt down the masses of molten that had chilled on top. Again, with this 200,000btu heat source I had to be very careful of the aluminum. So the basic technique, spread out over several sessions a day, for a week, worked quite well and my back muscles managed to keep pace. I ladled in about 2000 lbs of lead, 15-20 lbs at a time.

As the piles of ingots dwindled, I kept wondering if it would all fit into the keel compartments.I had 12, 573 lbs prepared, thinking I needed 12, 500. In reality though, 5500 kg (called for on the plans) is 12,100 lbs. So when I had about 700 lbs of ingots left over, it meant I was really only about 300 lbs shy. We’ll make up for that weight with canned beans, and Helen’s wine cellar.

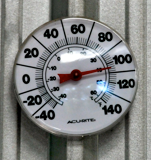

Wall thermometer in shade on the outside of shop, 8/3/11